►Capacitive Touch Switch

What is capacitive touch switch?

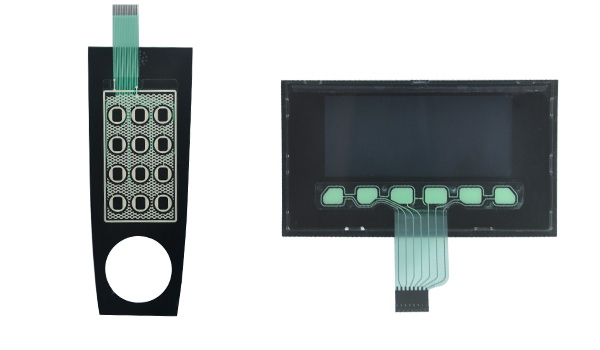

Capacitive touch switch combined normal panel and capacitive sensor together.Unlike traditional push-button switches, capacitive switches don’t need press,.Only put finger on the button in the sensing area, can be recognized by the machine through the film sensor operation.Most of the buttons are made by acrylic panels or injection parts with backlight display function which has a good appearance .Capacitive keypad has a fashionable appearance and long service life, so it has great advantages in many applications such as smart home appliances, cars, mobile phone communication, medical instruments and toys.

How does it work?

Induction capacitance exists between any two conductive objects. A key, namely a solder pad can also constitute an induction capacitance with the ground. The value of the induction capacitance is a small fixed value under the condition that the surrounding environment remains unchanged. A tension is normally applied on the four angles of the panel and it is uniformly widespread on all the surface of the screen; When human fingers are close to the touch button, the inductive capacitance formed by human fingers and the ground will increase the value of the total inductive capacitance. Capacitive touch key IC will output a certain signal when it detects that the inductive capacitance value of a key has changed. As there is no mechanical structure for the capacitive touch key, all the detection is a small change in the electric quantity, so it is more sensitive to all kinds of interference. Therefore, the design of the sensor and the selection of touch IC are very critical.

Topflight capacitive touch switches can be produced in polyester or other film materials, and they allow a wide freedom to the designer for any type of graphic solutions and for a backlighting of great impact and effect. When you order your custom capacitive switch from Flexkys, it ships complete with the sensor circuit, decorative graphics and your desired touch surface. We can also provide your capacitive switch with or without the front panels.

Advantages of Capacitive Touch Switches comparing to traditional Membrane Switches

•Long service life, the key usually has life in 5-10 years, and is not limited by the use of times

•Water immune and dust proof solutions

•Very easy and low cost to be backlit

•Combined with injection molding inside the film to produce IME parts or more decorative panels of different shapes

•Stylish appearance, flexible design, glass, acrylic, PC can be used as decorative panels, printed with any arts and patterns

•Can incorporate haptic feedback

•Line noise elimination

•Multiple keys or sliders

•Extremely fast touch response -160 milliseconds

•Very low current requirements

•Single or multiple cells – touch screens

•An excellent solution for product upgrades or retrofitting

•Configurable: I2C, SPI, TTL Serial UART, USB HID, RS232, RS485

•Affordable technology

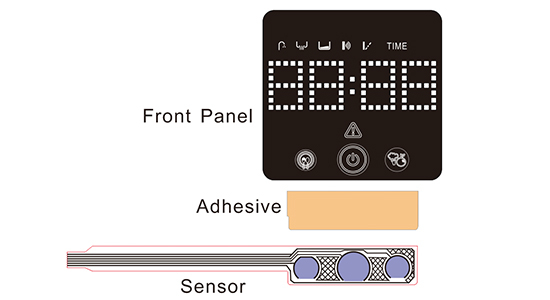

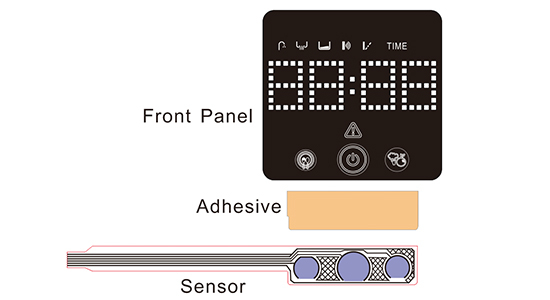

►structure presentation

How to design the sensor?

1.Optional materials to make sensor

How to design the sensor?

1.Optional materials to make sensor

As the circuit part of the capacitive switch, sensor can be made of silver printed circuit, transparent conductive ink printed circuit (for backlit solution), FPC (copper printed circuit), or hard PCB board.

2.Sensor PAD shape

In principle, it can be made into any shape according to the design of the panel keys.

3.Sensor PAD area size

Sensor PAD sizes are typically between 8*8mm and 15*15mm. If you have special requirements, we can customize for you. The actual size of the area is determined according to the requirements of the sensitivity, and the size of the area is proportional to the sensitivity. The distance between PAD and PAD should be at least 1mm, and the larger the distance is, the more beneficial it is to reduce the mutual interference between PADs.

4.Distance from sensor to front panel

In general, the sensor is directly attached to the back of the panel, with a very small distance between them.

►Normal materials

Front panel

1.Front panel materials

The panel must be made of insulating materials, such as glass, PC, PET, acrylic, etc. No metal is allowed within the key position. The metal within 50mm of the touch key must be grounded, otherwise the metal will affect the sensitivity of the key. In the production process, we need maintain the panel material and thickness unchanged, the panel surface coating must be used by insulation paint material.

2.Front panel thickness

To ensure the sensitivity of the keys, the thickness of the panel should be set between 0.2 and 4mm.

3.Double sided adhesive

Normally, the sensor is attached to the panel by double-sided adhesive. 3M 468 or OCA type glue can be used.

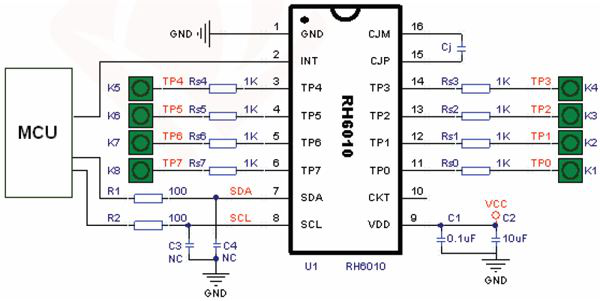

Touch IC

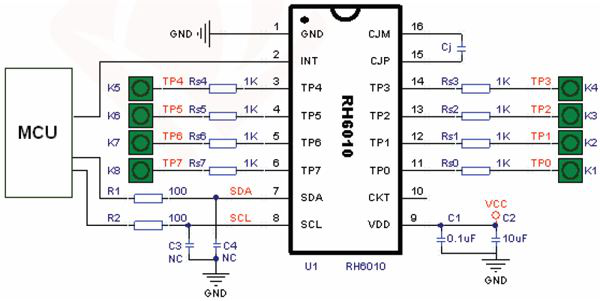

At present, the world famous electronic components suppliers are increasing the application of capacitive touch key IC research, and launched a number of professional touch chips, there are also many ICs based on MCU integrated class. Designers have large selection space, can choose suitable IC design according to the functional requirements and chip price, also can achieve touch IC by self design based on MCU A/D mouth.

Referred example for application principle

There are total 8 keys, respectively, K1 ~ K8

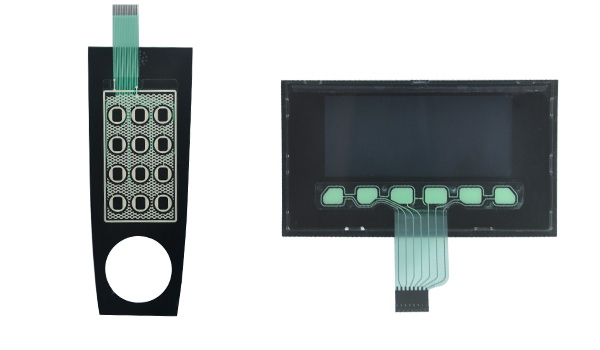

►Products

►Products